sandwich panels

PP Honeycomb, Balsa und foam are basic materials for light and rigid sandwich panels. Which material is most suitable for your application depends on the required laminate properties. Those could be low weight, high impact strength, thermal insulation, longterm stability, sound and vibration damping, water resistance, chemical resistance, shear strength and many more. Most of these basic materials can be supplied with additional fiber reinforced layers on both sides.

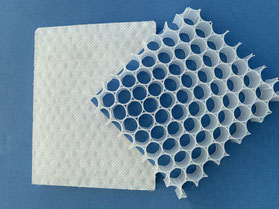

PP Honeycomb

Thermoplastic (polypropylene, PP) honeycomb

combines many unique advantages:

- Very lightweight

- Cost-effective

- 100% recyclable

- High compression & shear strength

With open cells or PES scrim (PP film + polyester veil)

Comes in 1220 x 2440 mm standard sheet size,

density: 80 kg/m³, cell size: 8mm

Other specifications available upon request.

Balsa

Our end grain Balsa is sourced exclusively from Ecuador.

It is a natural, renewable and recyclable material with unique weight-specific mechanical properties.

Quality approved by DNV GL and Lloyd‘s Register.

Standard sheet size is 610 x 1220 mm and density 280 kg/m³

Available in rigid sheets or in flexible (grid-scored) version with a glassfibre scrim.

Further options upon request include:

- Thickness: from 6 mm to 75 mm (1/4" to 3")

- Density: from 100 kg/m³ to 280 kg/m³

- Finish: coated (epoxy-based), perforated, parallel or crosswise grooves (1 or 2 sides), vacuum infusion cut (crosswise grooves 1 or 2 sides + perforations)

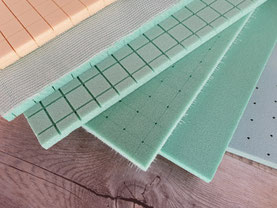

PVC foam

We offer PVC foam with a variety of different finishes, such as plain, perforated, double-cut, with grooves etc.

- PVC (polyvinyl chloride): damage tolerant foam core with consistently outstanding mechanical properties and excellent bonding to outer skin for heavy-duty applications.

Composite Panels

Composite panels made of PP Honeycomb core with

- skin layers of woven roving and thermoplastic matrix (TPH Panel)

- skin layers of glassfibre with polyester resin and gelcoat (FGH Panel)

Various finishes possible, such as anti slippery surface, coloured gelcoat etc.

FRF Panels

Fibre-reinforced foam panels offer high specific strength and toughness.

- FRF-VM (reinforced with continuous mat) density: 240 kg/m³, 320 kg/m³

- FRF-WR (reinforced with woven roving) density: 384 kg/m³, 416 kg/m³, 448 kg/m³

Standard sheet size: 96“x48“ (2440 x 1220 mm)

Common thicknesses: 3/8“, ½“, ¾“, 1“, 1 ½“ (6-38 mm)

Carbon Core Europe GmbH

Core materials for composite industry

Carbon Core Europe

International Solutions

Carbon Core Europe GmbH

Eibenweg 13

D - 47447 Moers

Fon: +49 (0) 2841 6086221

Fon: +49 (0) 2841 6086467

Email: info (at) carbon-core.de